| Author |  Topic Topic  |

melle

V4 Guru

United Kingdom

3833 Posts |  Posted - 06 Jun 2017 : 22:05:23 Posted - 06 Jun 2017 : 22:05:23

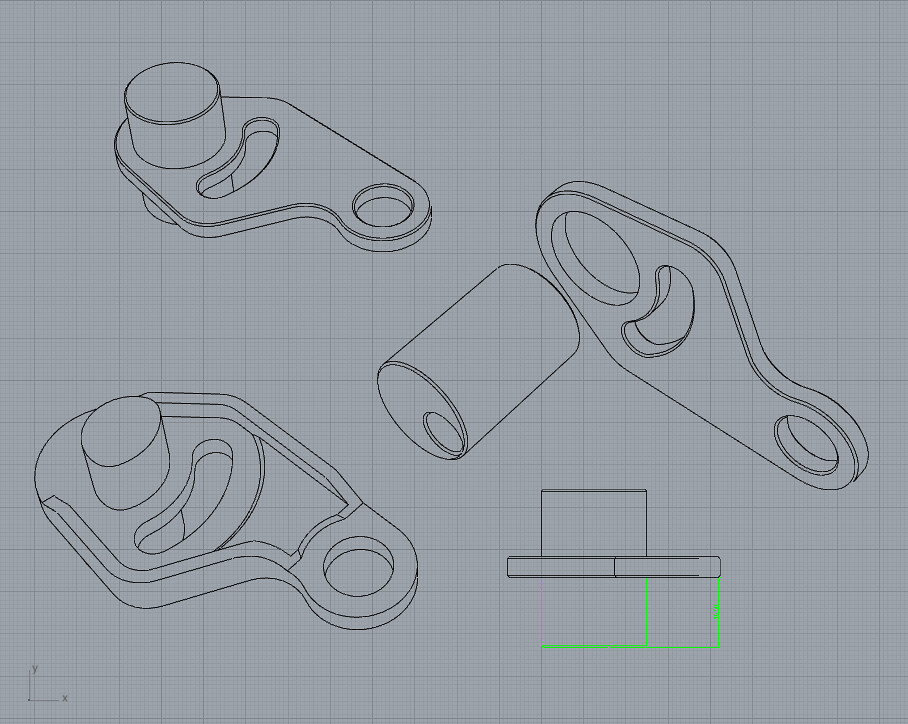

| Some people have reported issues with freewheel selectors breaking or melting and the cast iron two stroke item being a suitable alternative. As those are pretty thin on the ground, I thought I'd draw the plastic one in CAD and put it on my website so folks can have a go 3D-printing it. Whilst I was at it, I thought that as a trained industrial designer (with a slightly side-tracked career) I could do better.*

On basis of the plastic selector, I've designed a part (not unlike the two stroke item) that can be made by any amateur with the right tools from a piece of 90x50x5mm flat stock (mild steel, aluminium, stainless, ...) and some 25mm bar. The flat piece can be shaped with hand tools or a laser or water jet cutter if you have access to one. The bar can be machined on a small lathe with a 4-jaw chuck (it needs an excentric hole), or even with a pillar drill if you work carefully. The bar can be a shrink or Loctite fit in the flat piece or it can be welded in place, depending on what tools and skills are available. I'll put a set of drawings and cutting files (for both manual and CNC cutting) up on my website when I've made and tested a prototype and paste a link here. If anyone else wants to have a go before I find the time to knock one up (could be a while...), let me know and I'll email you the files when they're ready.

As this is desktop engineering at the moment and I don't have a gearbox handy to verify, does anyone have a two stroke selector available that they can take a measurement off for me? I basically need to know the length of the piece of bar that goes into the gearbox (indicated in green in below sketch). The plastic selector is moulded, hence a bit more advanced in shape than needed in metal, but I need to know what design features I need to retain. A pic of the underside of the selector would help as well. Thanks in advance!

(top left: metal selector design/ top right: metal selector design individual parts/ bottom left: plastic V4 selector/ bottom right: the dimension I need in green)

*And apart from that, as Herbert Simon said: "Designing is a kind of mental window shopping. Purchases do not have to be made to get pleasure from it." (in: The Sciences of the Artificial).

www.saabv4.com |

Edited by - melle on 06 Jun 2017 22:05:46 |

|

RhysN

V4 Fanatic

United Kingdom

411 Posts |  Posted - 07 Jun 2017 : 08:05:21 Posted - 07 Jun 2017 : 08:05:21

| | Would you like me to talk with my friendly laser cutter to ask about having a few cut? It seems like this might be a "nice thing" to have on the shelf for the day when your current one gives up? |  |

|

melle

V4 Guru

United Kingdom

3833 Posts |  Posted - 07 Jun 2017 : 12:09:45 Posted - 07 Jun 2017 : 12:09:45

| I really don't want to venture into parts production, I'm only interested in sharing knowledge and digital resources. When done, the files will be freely available to anyone who wants them for personal use. If someone wants to use the files commercially (and I have no doubt they will eventually), they better donate a whack of money to a good cause to clear their conscience as I can't and won't stop them. Please all support your local engineering firms and have the parts made locally.

PS: I'd rather have one of these in the car than on the shelf waiting for its day...

www.saabv4.com |  |

|

stevebod

V4 Fanatic

United Kingdom

416 Posts |  Posted - 07 Jun 2017 : 12:47:26 Posted - 07 Jun 2017 : 12:47:26

| Nice work Melle. I like your drawings.

On a related point. It is possible to drill an off-centre hole in some bar stock using just the 3-Jaw chuck on the lathe and some packing.

Like this.

A formula to calculate the size of the packing is:

Packing = 1.5 x offset x (1 - (1/8 x (Offset / Bar Diameter)))

Where offset is the distance from the centre of the hole to the centre of the bar stock; and Bar Diameter is the diameter of the body of the part.

Just mentioning in case anyone is going to make one as it is a bit of a time saver (and hopefully of some interest too). |  |

|

Betsy67

V4 Fanatic

United Kingdom

409 Posts |  Posted - 07 Jun 2017 : 12:52:50 Posted - 07 Jun 2017 : 12:52:50

| | Nice little read and design drawings. |  |

|

melle

V4 Guru

United Kingdom

3833 Posts |  Posted - 07 Jun 2017 : 13:27:57 Posted - 07 Jun 2017 : 13:27:57

| Great tip on using a 3-jaw for this Steve! We have a 4-jaw chuck on my father in law's big lathe, but for the new-to-me small Wolf Jahn I'm still on the lookout for a 4" or 5" 4-jaw. Good to know that doesn't have to stop me from making a metal selector. My mate has a water jet cutting company, will ask him to cut out the flat piece for me.

What I really like in copying parts (I did this a lot when learning CAD 10 years ago), is that by decomposing them you can see how the original designer has worked and whether they worked in millimetres or inches. Most compound shapes are built up from simple geometric elements, remember that parts like this were designed with a ruler and a compass back in the day!

www.saabv4.com |  |

|

melle

V4 Guru

United Kingdom

3833 Posts |  Posted - 07 Jun 2017 : 13:31:55 Posted - 07 Jun 2017 : 13:31:55

| By the way: I never use the freewheel and have the handle blocked with a piece of PVC pipe, so this is really only a fun little project for me to keep my CAD skills on par. I've also done a Ronal centre cap last week if anyone wants to 3D-print one, will upload the file to my website later.

www.saabv4.com |

Edited by - melle on 07 Jun 2017 13:33:13 |  |

|

Woody

V4 Guru

United Kingdom

2764 Posts |  Posted - 09 Jun 2017 : 19:59:44 Posted - 09 Jun 2017 : 19:59:44

| the gap between side of pillar and the rule aligned with edge of arm is 3mm

|

Edited by - Woody on 09 Jun 2017 20:02:25 |  |

|

melle

V4 Guru

United Kingdom

3833 Posts |  Posted - 09 Jun 2017 : 20:05:36 Posted - 09 Jun 2017 : 20:05:36

| Thanks, but I actually meant the hight of the bit of bar to the underside of the "arm"/ flat piece, bit unclear in my sketch perhaps.

www.saabv4.com |  |

|

RhysN

V4 Fanatic

United Kingdom

411 Posts |  Posted - 09 Jun 2017 : 21:24:24 Posted - 09 Jun 2017 : 21:24:24

| I was not meaning to go into parts production, just to facilitate anyone who wanted them cut. Melle I am sorry if I offended you. I have always passed things on at what they have cost me, or in many cases given them away.

Again apologies, obviously as a new immigrant to this country my efforts to help others are perceived as somewhat unusual, and seen as suspicious.

In cases like this, I have managed to locate people who can do these tasks, but doing a multiple is cheaper than one at a time. The same applied to the brake bits, and piston pins, I won't do other than find my own things any more, nor will I try to give bits to others who can't find them.

My conscience is now clear. |  |

|

melle

V4 Guru

United Kingdom

3833 Posts |  Posted - 09 Jun 2017 : 22:00:41 Posted - 09 Jun 2017 : 22:00:41

| Rhys, no worries mate, you have in no way offended me. I'm sorry you read something completely different in my post than I intended, my sincere apologies for the poor wording. It's great you offer to have some parts cut to help others and you're most welcome to the files when I've finished them, I certainly wasn't accusing you of commercial intentions! Again, sorry if I was unclear, blame it on English not being my mother tongue.

www.saabv4.com |  |

|

Woody

V4 Guru

United Kingdom

2764 Posts |  Posted - 09 Jun 2017 : 22:35:38 Posted - 09 Jun 2017 : 22:35:38

| The diagram appeared not as clear on my wife's ipad mini. Better on the larger screen of her laptop.

The height is 22.05 mm. |  |

|

melle

V4 Guru

United Kingdom

3833 Posts | |

RhysN

V4 Fanatic

United Kingdom

411 Posts |  Posted - 10 Jun 2017 : 10:12:18 Posted - 10 Jun 2017 : 10:12:18

| | I am pleased I haven't upset you Melle. You are far too valuable a resource to annoy. |  |

|

green96v4

V4 Mad

Canada

738 Posts |  Posted - 10 Jun 2017 : 10:54:55 Posted - 10 Jun 2017 : 10:54:55

| Rhys - I would still be very interested in the brake pins, my resto is running beautifully now apart from the annoying thumping on the brake caliper!

quote:

Originally posted by RhysN

I was not meaning to go into parts production, just to facilitate anyone who wanted them cut. Melle I am sorry if I offended you. I have always passed things on at what they have cost me, or in many cases given them away.

Again apologies, obviously as a new immigrant to this country my efforts to help others are perceived as somewhat unusual, and seen as suspicious.

In cases like this, I have managed to locate people who can do these tasks, but doing a multiple is cheaper than one at a time. The same applied to the brake bits, and piston pins, I won't do other than find my own things any more, nor will I try to give bits to others who can't find them.

My conscience is now clear.

|  |

|

RhysN

V4 Fanatic

United Kingdom

411 Posts |  Posted - 10 Jun 2017 : 12:23:07 Posted - 10 Jun 2017 : 12:23:07

| | The person who needs to do the research on this returns from holiday today. I still need to find a sample set, good or bad, to work from. |  |

|

Topic Topic  | |